Dealing with Hard-to-Treat Industrial Wastewater

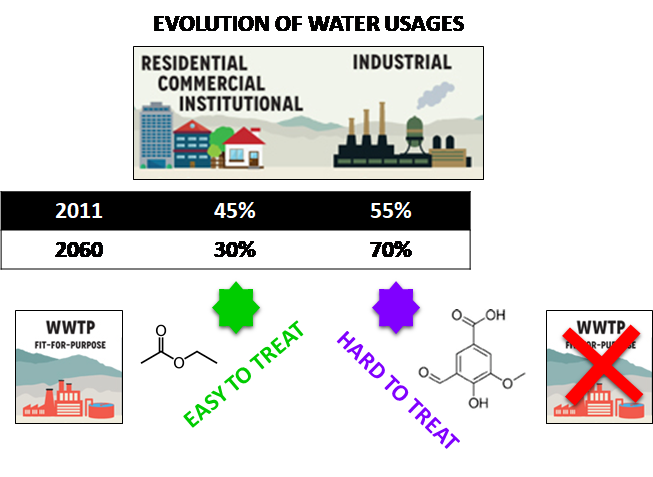

In Singapore, more than 50% of the water demand is used by the industry and this proportion is expected to reach 70% by 2060. Specific electrochemical advanced oxidation technologies are being developed to deal with this specific kind of wastewater

characterized by high organic load and toxicity.

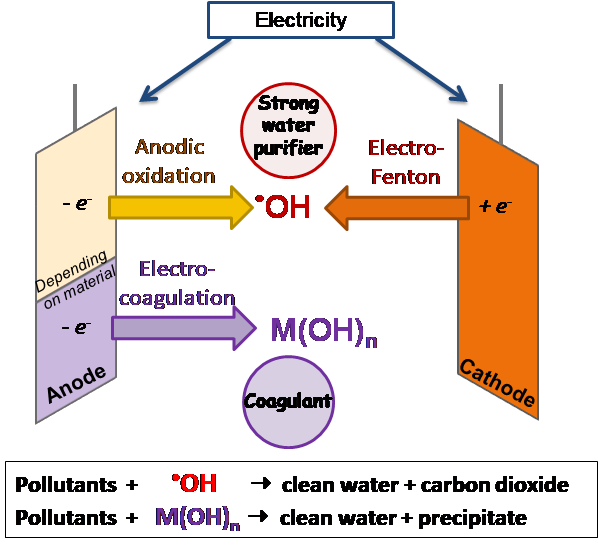

Cleaning water with electricity

The treatment of industrial wastewater is a challenge, especially for highly concentrated streams generated by various sectors, such as chemical and petrochemical, pharmaceutical, microelectronics, etc. In many cases, the waste streams can have COD concentrations in excess of 10,000 mg/L and sometimes up to 100,000 mg/L or even higher. These concentrations are several orders of magnitude higher than domestic wastewater or sewage that the water industry typically deals with and there exists no gold solution to treat such streams effectively. Conventional techniques relying on the so-called activated sludge or other biological techniques often prove ineffective to deal with the toxicity associated with the many chemicals present in industrial wastewater and in most cases incineration remains the only option, despite prohibitive costs.

Electrochemical advanced oxidation relies on the use of advanced electrode materials to generate the hydroxyl radicals needed to degrade and mineralize the complex organics present in this type of hard-to-treat high COD industrial wastewater under ambient conditions. This process sometimes referred to as “cold incineration” has the advantage of being able to deal with any kind of organic chemicals present in wastewater at

a cost more than 10 times lower than conventional “hot” incineration. Compared to other advanced oxidation processes (AOP), the reagent for purification is produced within the waste itself using electricity instead of chemicals and with no harmful emission. This provides electrochemical approaches the advantage of better mass transfer and applicability on concentrated industrial wastewater.

The NUS researchers focus on finding the best materials and operating conditions, elucidating the degradation pathways and system scale-up for real applications in the industry.

For more details, please contact:

Associate Professor Olivier Patrick LEFEBVRE

E-mail: ceelop@nus.edu.sg