Waste is not a Waste but a Misplaced Resource

– Turning Wastes into Resources for Civil and Environmental Applications

WASTE FROM INCINERATION

Both carbon black waste and ash are the unavoidable by-products produced in huge amounts by incineration of industrial wastes. Carbon black waste is produced from gasification of crude oil bottoms whereas ash is a residual component of sewage sludge and municipal solid wastes after incineration. If not reused, they will be sent to Singapore’s only landfill, Semakau Island. However, these materials contain toxins like heavy metals, polycyclic aromatic hydrocarbons (PAHs), etc at high level concentration which can potentially pose adverse environmental impacts to the surrounding aquatic systems. Re-utilising the wastes by turning those into resources are therefore important to ensure more sustainable management of the solid wastes.

GREEN APPROACH TO CONVERT INCINERATION WASTE TO FUNCTIONAL CIVIL & ENVIRONMENTAL APPLICATION MATERIALS

Professor Wang Chi-Hwa and his research team have developed an efficient approach to remove the heavy metals from the wastes by using a greener organic acid and thus limit its leaching into water bodies. Compared to the conventional method which involves the use of hazardous acids such as sulphuric acid, the acid used by the team is biodegradable. Hence, this minimises impact to the environmental. The wastes after the treatment can then be used to make into functional materials for civil and environmental applications such as construction material where there is a demand for vast quantities of material.

AEROGEL FROM CARBON BLACK WASTE

One recent development from the research team is using the treated carbon black waste to make lightweight, highly porous sorbent or so-called aerogel for separation of oils and organic compounds from water. Carbon black waste contains numerous tiny pores which provide abundant site for sorption. However, carbon black waste in powder form is difficult to separate after use which restricted its application.

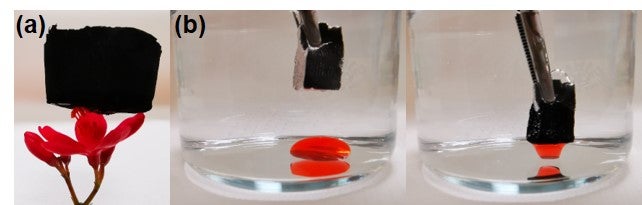

Figure 1: (a) Low density carbon-based sorbent rested on a flower petal. (b) Underwater oil adsorption by the sorbent.

The 3-dimensional aerogel constructed by the research team eases the separation and collection for reuse. Moreover, after appropriate surface modification, the aerogel poses superhydrophobic property that makes it effectively repel water while absorbing oils and various organic compounds. Taking the advantage of its superior selectivity and high porosity, the aerogel could adsorb up to 35 times its original weight. Through a simply drying method, the used aerogel could be readily recovered and reused repeatedly. The aerogel developed by Professor Wang and his research team has high potential application in remediation of oil spills and oily wastewater treatment.

GEOPOLYMER FROM WOOD FLY ASH

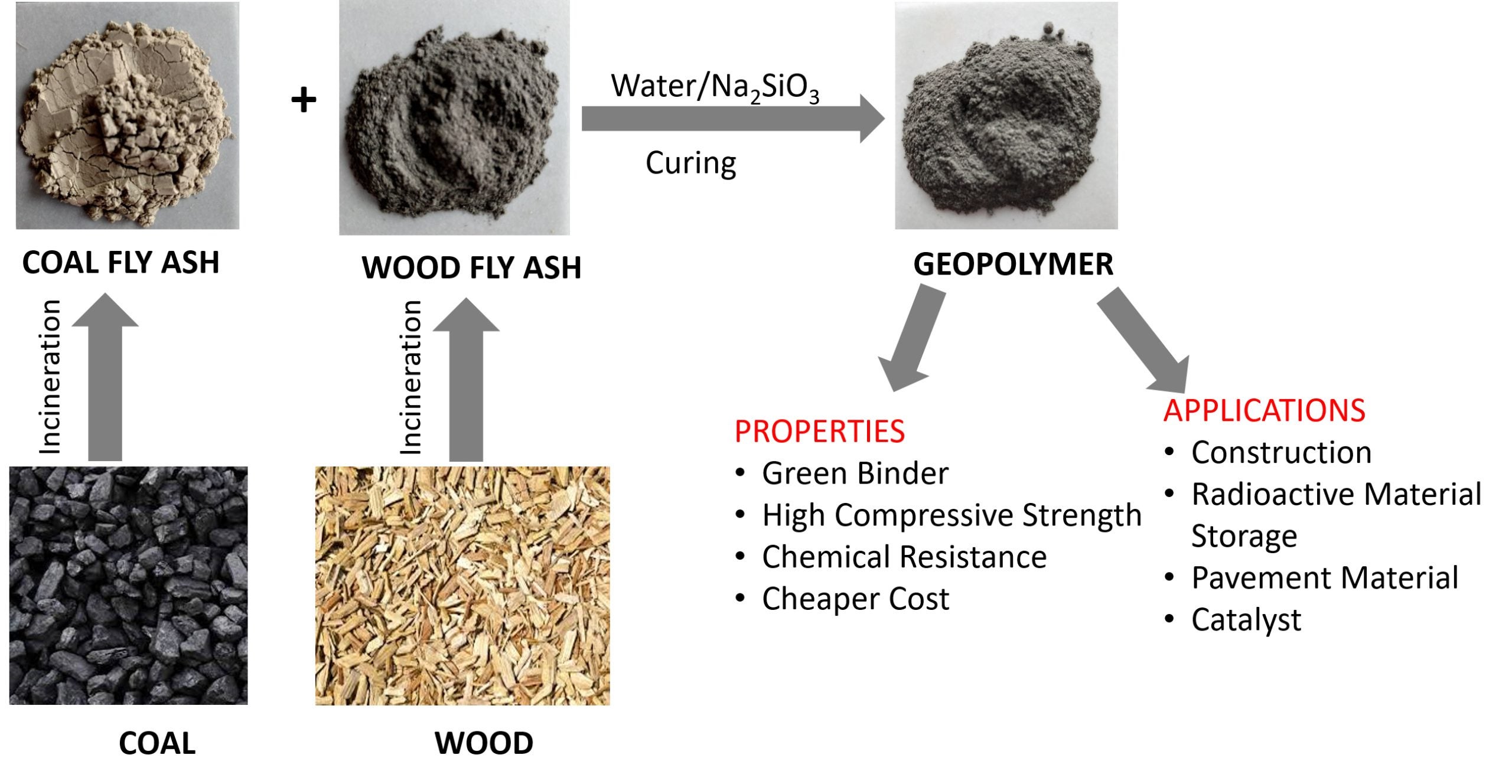

Professor Wang and his research team are also exploring the use of wood fly ash as an alkaline activator for the production of geopolymer (a greener alternative to cement, using coal fly ash). Usually an external activator like sodium silicate is used for the geopolymer production, which increases the cost of the process and requires skilled handling. Here wood fly ash is used as an activator which reduces the overall cost and also facilitates ash recycling. Various process parameters were tuned and formulations were tried using internal/external activators and it was discovered that using wood fly ash alone resulted in geopolymer production that leached out the least in terms of heavy metal. A cost estimation analysis showed that the produced material is cheaper than the conventional cement used in concrete and is thus promising.

Figure 2: Conversion of coal fly ash & wood fly ash to geopolymer.

PROGRESS TOWARDS ENHANCED SUSTAINABILITY

The team is venturing further on process optimisation to lower the cost and environmental impacts associated with generation of by-products and chemical disposal. Professor Wang and his research team are maximising the use of green reagents, tuning the process parameters to reduce the chemical demand and cost for simpler solutions to treat/ modify the waste effectively on a commercial scale. For carbon black wastes, its usage will be extended to remove a broader range of organic contaminants in order to meet the industrial needs. This requires the chemical modification to the pristine carbon black wastes and design of scalable synthesis process which is currently in the progress.

For more details, please contact

Professor WANG Chi-Hwa

E-mail: chewch@nus.edu.sg

Publications:

- Lin, W.Y., Prabhakar, A.K., Mohan, B.C. and Wang, C.H., 2020. A factorial experimental analysis of using wood fly ash as an alkaline activator along with coal fly ash for production of geopolymer-cementitious hybrids. Science of The Total Environment, 718, p.135289.

- Tai, M.H., Mohan, B.C., Yao, Z. and Wang, C.H., 2022. Superhydrophobic leached carbon Black/Poly (vinyl) alcohol aerogel for selective removal of oils and organic compounds from water. Chemosphere, 286, p.131520.