The Bread Winners

Partners in life and in business, Ms Pranoti Nagarkar (Engineering ’03) and Mr Rishi Israni (Computing ’03) turned a dinner conversation into the world’s first flatbread-making robot, Rotimatic.

WHO ARE THEY?

Ms Pranoti Nagarkar and Mr Rishi Israni are the inventors of Rotimatic, an automated kitchen appliance that makes flatbread. Their company, Zimplistic Pte Ltd., was incubated in Singapore. Rotimatic is Zimplistic’s flagship product, and the company is headquartered in Mountain View, California.

Big things often have small beginnings — and we need not only look to Hollywood (Prometheus, anyone?) for examples of that. “The idea came to us during a dinner conversation when Rishi and I were not happy with the food we were eating after a long day at work. Despite all our modern comforts, we still didn’t have a solution to help us get fresh homemade rotis, a staple for South Asians,” says Ms Pranoti Nagarkar, 36, Chief Technology Officer at Zimplistic Pte Ltd. Together with her husband, Zimplistic’s Chief Executive Officer Mr Rishi Israni, also 36, she invented Rotimatic, the world’s first machine that employs artificial intelligence (AI) to produce rotis, or flatbreads, in a matter of seconds. This is no small feat, seeing that making fresh chapatis by hand requires a lot of time, effort and skill. “I had to find a solution as hundreds of millions of human hours go into making five billion rotis for daily consumption,” says Ms Nagarkar. “This is the bigger purpose which has been the glue that kept us motivated throughout the journey. If we stopped, the problem would not have been solved — this is what kept us going through all the ups and downs.”

Now both Singapore Citizens, the couple originally hail from India: Ms Nagarkar from Pune, Maharashtra, and Mr Israni from Lucknow. Both attended NUS and met through club activities there. They have a five-year-old son, Orit, and at the time of this interview, are expecting their second child in April. Ms Nagarkar always had the drive of an inventor. “I majored in Mechanical Engineering and the biggest contributor to my Rotimatic journey was the one-year-long design project I did as a student where I built an automatic ironing machine for shirts. It involved using all the theory I had studied, as well as being hands-on in building the prototype from actual physical materials. It exposed me to the realities of product design — from technical constraints to the needs of the user, and how to think about pricing it. It was this experience that instilled in me the confidence of inventing, creating and building products that can solve human problems.”

In 2008, after two years as a product design engineer for Amtek Innovation Design Centre, she set about turning her dream of building a roti machine into reality. Zimplistic — she had wanted “Simplistic” but the name was taken — was registered and operated out of NUS Enterprise’s startup hub, BLOCK71. “I started working on it first, conceptualising in detail and kicked off prototyping,” says Ms Nagarkar, who wrote eight patents for Rotimatic in the process. In 2009, Zimplistic won the Start-Up@Singapore business plan competition.

I believe that we all have equal capabilities, but the difference in the pursuit of excellence stems from the standards one sets for himself or herself.

Mr Rishi Israni

Mr Israni, at that point, was the co-founder and CTO of mobile security startup, tenCube. When the company was acquired by McAfee in 2010, he became its Director for Consumer Mobile Technology. In 2011, he joined his wife as the CEO of Zimplistic. “Rotimatic’s mechanical system worked but it was not very reliable, given the variations in a mechanical system,” he explains. “It became clear that we would need to build intelligence into the machine. That’s why Pranoti hired me.” He introduced AI and IoT capabilities to the machine, writing the software and authoring six patents. Despite initial adjustments they needed to make to accommodate each other’s working styles, their different strengths and expertise proved to be a marriage made in heaven. “That combination became the 'secret sauce' as we could combine the best of both worlds seamlessly to solve challenges we faced in building Rotimatic.”

FLOUR POWER

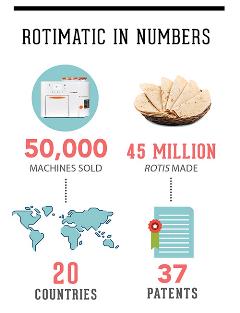

Rotimatic was introduced to the world in 2015, and its initial 8,500 machines were sold out within weeks. Right on the IoT trend, Rotimatic is a “smart” machine that is powered with AI. Once connected to WiFi, the machine’s software is updated automatically and remote troubleshooting is possible. The machine measures, mixes, kneads, rolls, cooks and puffs a roti in 90 seconds; users can even customise the thickness and roast level of their flatbreads. Rotimatic even mimics human judgment to adjust the proportion of flour to water to ensure consistency. The result is a golden-brown chapati that is soft and fluffy on the inside, every time. All the user needs to do is fill up the water tank and the flour dispenser, and press a button. The machine is even easy to clean.

The Computing connection

A graduate from the School of Computing in NUS, Mr Israni credits his time at the faculty with shaping the way he thought about robotising Rotimatic.

“I remember a Data Structure module I took. At the end of every week or two, there was a practical quiz for the cohort, an automated examination system that would automatically check for plagiarism and rate your solution against others’. As a young Computer Science student, I found it fascinating and ahead of its time. It certainly triggered my love for building innovative applications with technology. A few semesters down the road, I took an AI module where we explored the possibilities of bringing intelligence to machines. It planted a seed in my mind which came full circle when I encountered the problem while working on Rotimatic. At NUS, I also did a project which involved building contactless mobile payment systems — which was a huge leap at the time. So many such experiences and instances of exposure at the School of Computing laid the foundation for the technology entrepreneurship career I pursued after graduation.”

Not surprisingly, Rotimatic’s launch sparked huge interest worldwide, with the

Wall Street Journal blogging it to be “the best thing since sliced bread” and

Fortune doing a show-and-tell demo video of the device featuring Ms Nagarkar on its website. Prime Minister Lee Hsien Loong only added to its popularity by praising Zimplistic and its invention in his 2016 National Day speech. Mr Israni, however, is quick to point out that improvement and innovation are a continual process for Zimplistic. “Every product is different and all insights about the process are the benefit of hindsight,” he says, referring to a picture on his office wall that shows the creation process is not at all a straight line but a tornado of multidirectional squiggles and complexities. “You hope to reach a certain outcome, but constantly fail and iterate. You keep a strong grasp of the core principles and keep a clear sight of the big objective — the rest is that meandering journey.”

The “core principles” which Mr Israni talks about definitely are in sync with Ms Nagarkar’s criteria for success, which, for the first generation of Rotimatic, was “for it to be a great choice for a family which wants to eat healthy homemade

rotis. So we had a clear picture of the user-experience,” she says. “We knew the size it had to be, the price point, the ease of operation as well as cleaning afterwards — the end-to-end automation to enable fresh homemade eating.”

Rolling in The Dough

Zimplistic made $20 million in its first year, but what is more impressive is their vision to scale up the machine and the business — already, since launching, the company has been adding features and software updates for users to continue discovering new ways to enjoy their Rotimatics. Besides

roti, one can make pizza bases and

puri discs, and soon tortillas and gluten-free flatbreads. Zimplistic successfully raised $39 million last year to fund expansion. “Our first platform has done really well. We are working on the next generation of Rotimatic which is better on all parameters — it’s the one which is going to give us real scale and reach the millions who eat flatbread daily,” says Mr Israni. Their aim is to convert 25 per cent of the world’s flatbread-eating population to Rotimatic users. “I believe that we all have equal capabilities, but the difference in the pursuit of excellence stems from the standards one sets for himself or herself,” he adds. “These standards are a result of one’s exposure, ambitions and awareness. When someone sets their eyes on the right problem and pursues with a mindset of only accepting the most excellent solution, it naturally drives the individual to keep trying, despite setbacks and temporary failures.”